No cutting , various types of DOC, DPF, and SCR do not need to be decomposed

Short time,During regeneration, The total time is shortened to 40 minutes.

Good effect, automatically turns on the high temperature and high pressure purge mode, and the carbon deposits are not retained.

Tel:0086-18253885135

Email: info@beacon-machine.com

Intelligent post-processing regeneration intelligent collar version

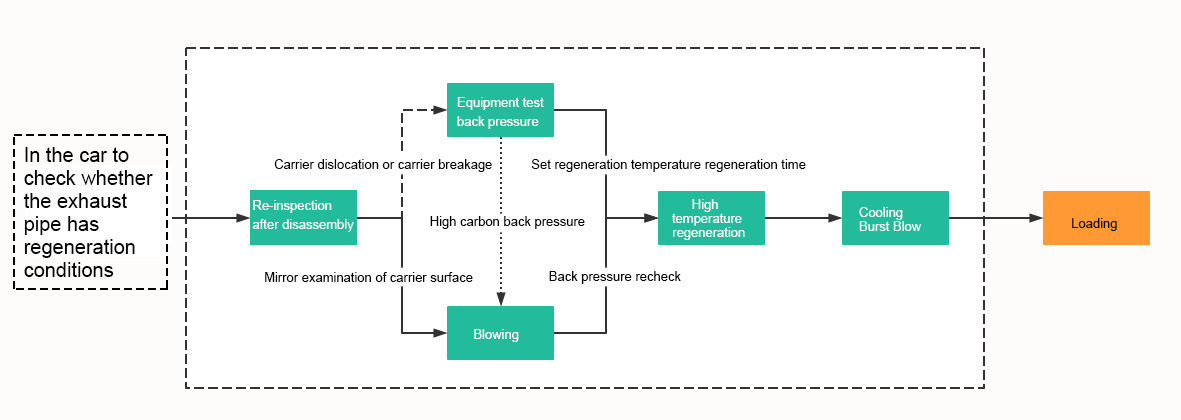

Flow chart of exhaust pipe regeneration

Special attention; Before starting the regeneration, perform a pressure test on the equipment to determine if there is gas discharge at the tail end of the exhaust pipe and if there is any leakage at the connections. After the regeneration back pressure exceeds 40KPa, the equipment will alarm and check if the carrier has been washed, displaced, sintered, and does not have the ability to regenerate. It is recommended to replace the carrier.

Special attention; Before starting the regeneration, perform a pressure test on the equipment to determine if there is gas discharge at the tail end of the exhaust pipe and if there is any leakage at the connections. After the regeneration back pressure exceeds 40KPa, the equipment will alarm and check if the carrier has been washed, displaced, sintered, and does not have the ability to regenerate. It is recommended to replace the carrier.

Handling methods; First, clean or blow out the exhaust pipe until the back pressure drops below 35KPa, and perform preliminary dredging at a regeneration temperature of around 200 degrees until gas is discharged from the tail end of the exhaust pipe! Only then can high-temperature regeneration be carried out.

Please check the alarm bar in a timely manner when the device is in an alarm state.

Equipment principle and function

Simulate vehicle regeneration, this equipment host is equivalent to an engine with no torsion limit and can continuously output 0-800 degrees of heat energy! During regeneration, it is heated directly from the core part, without heating through the insulation layer from outside to inside. It can be heated from 0 degrees to 800 degrees, keep the temperature and automatically open the high pressure purge mode. During the regeneration process, the carbon deposition and carbon ash have been basically cleaned up. More than 96% of the regeneration, perfect effect.

The operation interface adopts a high-definition touch screen, making human-machine communication more convenient. All operations can be completed on the screen!

The overall design of the host is simple and atmospheric, highlighting the tough industrial lines, and reasonable functional zoning, making the product more operable!

Automatically activate the fast cooling mode, and the temperature drops to around 40 degrees Celsius within 10 minutes. After regeneration, explosive blowing is used to completely remove residues in the exhaust pipe. It has been certified by authoritative institutions and has a high permeability after regeneration

1. The control system adopts programmable intelligent PLC control with multi-stage temperature control. It has automatic temperature rise and fall program, PID function, and high temperature control accuracy.

2. Real time pressure data, equipped with data printing function.

3. The high-temperature head is made of imported high-temperature movement, and the internal components are made of high-quality mica that is resistant to 1300 degrees, which is energy-saving. 4. The advantage of high temperature deformation resistance is matched with a quick connector and DPF connection, making it more convenient!

5. The heating effect saves 50% energy and electricity compared to the heating tube, and the DPF regeneration time is shortened to within 30 minutes!

6. Heating up to 0-800 degrees only takes 4 minutes!

7. The cooling time can be reduced from 800 degrees to 50 degrees in 3 minutes!

Turn on the power setting program, the device will automatically work and stop automatically after the work is completed. The equipment is energy-saving and efficient, easy to operate, fast to heat up, flexible and versatile, and has superior performance!

Equipment usage precautions and knowledge points

It is strictly prohibited to power off during equipment heating and use!

1) Before regeneration, check the back pressure of the exhaust pipe in the vehicle, and then conduct a test after regeneration to form a comparison before and after regeneration (the equipment shows that the back pressure can only be used as reference data before and after regeneration)

2) Adjust the time and temperature reasonably according to the size of the carrier and the degree of blockage in order to achieve the effect!

3) The high-temperature materials inside the high-pressure thermal energy converter are fragile! Ensure stable placement when connecting and fixing, with an angle not exceeding 45 degrees! Beware of severe vibrations, falls, and bumps!

4) After the device detects that the back pressure exceeds 40KP, it will display a high back pressure and alarm to automatically execute the initial temperature value. After the back pressure drops, the regeneration temperature will be executed. After the alarm is held, an emergency stop reset can be taken to execute the high air pressure alarm in the regeneration temperature and shutdown inspection.

5) The total operating time is a combination of heating time, holding time, and regeneration time

6) After the regeneration is completed, it is necessary to perform explosive blowing!

Check the cause of exhaust pipe blockage for reasonable regeneration;

1) The quality of urea crystallization is good or bad. The crystals formed by urea can be dissolved after using them well at a temperature of over 400 degrees. The crystals formed by secondary urea should be checked for carrier damage and displacement (it is recommended to replace the carrier)

2) For blockages in the exhaust pipe caused by square urea crystals, the first step is to treat them with large crystals before regeneration. The regeneration time should be extended as much as possible and outdoor operations should be carried out,

After regeneration is completed, cutting for high-pressure blowing and cleaning of the internal carrier has a better effect.