Tel:0086-18253885135

Email: info@beacon-machine.com

2:Main configurations

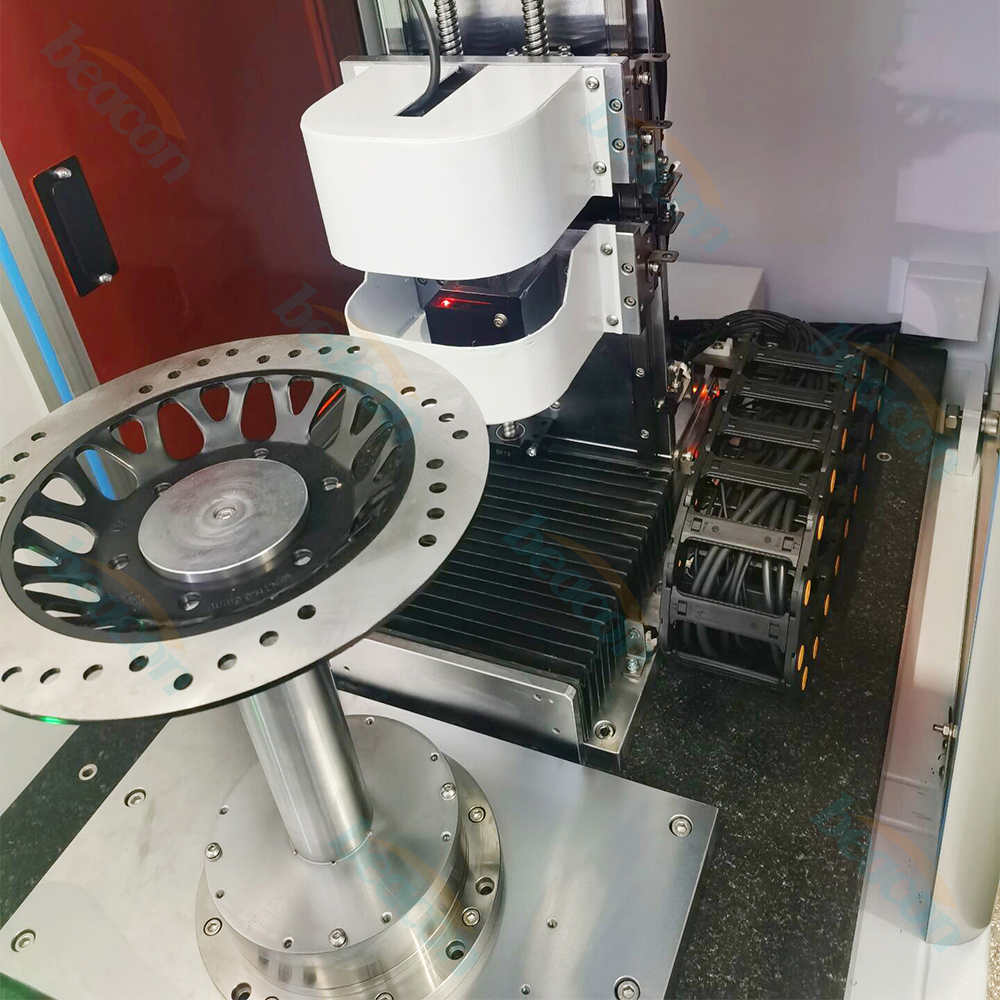

2.1 Instrument used: Sampling high-precision laser sensor, measurement range ± 3.7mm, linear Error: ± 0.015% F.S (actual testing accuracy reaches ± 0.94um) configured with Taiwan Advantech industrial control computer, brand I/O board, and motion control board.

2.2 Automatic removal of brake disc faces and grooves

2.3 Configure 1 set of 2-level measuring blocks for calibrating laser sensors. When changing the measurement specifications, it is necessary to adjust the position of the laser sensor and recalibrate it.

2.4 Mechanical part

The spindle adopts a high-precision air floating spindle, with an end face runout of less than 0.001mm. The horizontal axis is sampled by Japan THK high-precision linear guide rail

The two axis motion is driven by a servo motor.

3、Measurement plan:

The workpiece is installed on the air static pressure spindle, and a set of laser displacement sensors are installed on the upper and lower parts of the measuring arm. The sensors can move radially, and the workpiece rotates continuously. The sensors continuously sample on different circles, and the system automatically removes the groove part of the intermittent surface to evaluate the measured parameters.

Quickly switch product specifications by manually adjusting the sensor height by replacing the positioning table and centering shaft.

Workpiece thickness of 1.5-10mm, total height of workpiece less than 35mm, measurement area φ 100~ φ 340mm, the weight of the workpiece is less than 12Kg.